A pictorial essay on natural-dyed khadi

Natural dye is a long process, says Paresh Patel of Royal Brocades, Ridrol.

It takes two or three days to dye one colour.

Paresh Patel

Paresh Patel

Paresh Patel

Yarn Preparation

When raw cotton yarn comes to us, it has a lot of “kachra” dust and dirt.

We have to boil the yarn and remove the impurities.

Otherwise, the dye will not stick.

Indigo

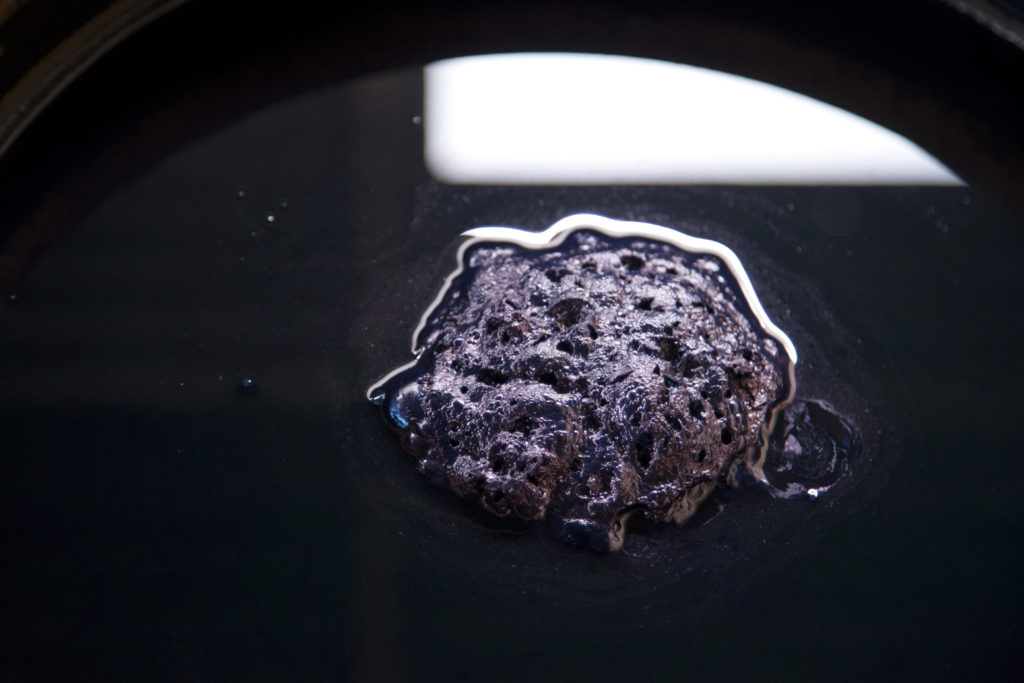

Black dye: iron rust with jaggery

Mordant: dye fixative

The Latin word “mordere” means “to bite.”

First, you apply mordant, which is pretreatment of yarn so that it absorbs the dye into the fibre.

We use alum for silk and alum, tannins and myrobalan for cotton. We use other compounds: ferrous sulphate, copper sulphate, copper (they call it moo-thoo-thoo)

But rather than chemical compounds, we use natural options. Like for ferrous sulphate, we use iron rust plus jaggery.

Indigo

Indigo is easy. It doesn’t need any pre-mordanting or anything. Just ready yarn.

Because “indigo fibre ke uppar,” it sits on top of the fibre.

As a result, if not done well, it will bleed and fade.

Like faded denim.

If there are impurities in the yarn, the indigo will not stick.

The colour will bleed.

Indigo

Other Colours

We use a lot of other colours.

Madder from the roots of Rubia species. Very common in Gujarat. We use alum to give shades of pink and red

Sappan wood is a favourite of mine. We get it from the wood of the Sappan tree. Lovely reddish colour

We can use morinda from the root and bark of the tree Morinda Citrifolia.

We can use turmeric: “Harda karenge, phir dye hoga.” We prepare the turmeric, then we dye.

Dyeing Process

The water is important. We pay attention to the Ph balance. Whether iron is high in the water.

In the past, we knew this from experience. Now we have tools to test the Ph.

For example, in hill stations, the dye will be different colour tone. Because they have minerals in the water.

Besides the quality of the water, humidity is also important.

The mordant is fixed on day 1.

On the second day, we dye. If desired color is not achieved, we dye again. On the third or fourth day also.

The Pleasure of Natural Dyes

Previously we used to do acid dyes. We still use them. They have chemicals. The smell of chemicals is not pleasant at all.

Natural dyes are different. They calm us down. The fragrance comes from the vat and fills the house the whole day.

This is why we begin the day with natural dyes.

The problem with mango-turmeric is that it doesn’t fix very well. This is why Tibetan monks have to dye their clothes again and again.

Our own cottons, we dye again and again.

Recipe for amba-hardar or mango-turmeric

Take some dry mango-turmeric. Dry amba-hardar

Remove the starch from the cloth

Soak for half hour in mango-turmeric solution. Don’t worry about the temperature.

Let it dry. Wear it.

You will smell good the whole day.

I am not fan of cloth dyeing. Yarn dyeing is better. Handling is easy. It is easy to manage the dyeing process. But if you want to try, you can do the mango-turmeric on clothes.